Supermarket refrigeration systems

Digital twins to enhance the super-market refrigeration business through advanced monitoring capabilities, efficient fault detection and diagnosis, and operational performance optimization.

Supermarket refrigeration systems

Supermarkets are responsible for approximately 3-4 % of the electricity consumption of industrialised countries. Up to 50 % of this consumption is attributed to refrigeration systems, especially to the power input to compressor racks, which account for about 25 % of the total consumption. Therefore, improving the energy efficiency of supermarkets is not only an economic issue but a key step to mitigate their environmental impact and align with the growing emphasis on sustainable and environmentally conscious business practices.

Digital twins are a powerful technology for monitoring, analyzing, and optimizing the operation of commercial refrigeration systems. In light of this, this project has aimed to develop a digital twin of a CO2 supermarket refrigeration system to:

- Investigate the dynamic interaction between the control action of the pack controller, which adjusts the compressor capacities according to the actual cooling loads and the cabinet thermostats. This was done because their mutual interaction was suspected to affect the energy consumption and the number of compressor starts and stops.

- Identify recommendations for better control solutions (building on the knowledge gained from the previous point) and assess their related energy-saving potential.

- Test the improved control measures/settings in real applications.

Digital twin framework

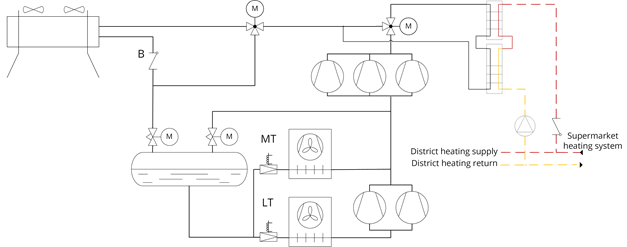

The modelling framework was developed based on the CO2 refrigeration system of the supermarket Fakta in Otterup (DK). This choice stemmed from the large amount of data available in this supermarket for model development and validation due to its participation in a previous research project. The layout of the CO2 refrigeration system (almost standard in Denmark) is shown in figure 1.

Figure 1: Simplified schematic of a CO2 supermarket refrigeration system with heat recovery.

The system consists of various subsystems such as two groups of evaporators, one for freezing at low temperatures (LT) and one for cooling at medium temperatures (MT), two expansion valves, two compression groups, a condenser/gas cooler, a high-pressure valve, a flash gas bypass valve, a liquid receiver, and potentially a heat recovery unit. For the different subsystems, the amount of knowledge about the system varies. This accounts for both the information about the specific construction as well as data associated with the operation of the units. Thus, this aspect requires different modelling approaches to exploit the resources most optimally while providing the required services.

Figure 2: Display cabinets (left) and compressor rack (right) from the Fakta store located in Otterup, Denmark.

Following the structure shown in figure 1, an analytical/numerical model, i.e. digital twin, was developed in Modelica using TIL Suite, an external library of TLK-Thermo which contains a wide range of models for modelling thermodynamic systems. The resulting model was then exported as a Functional Mock-up Unit and integrated into MATLAB, where it was coupled with a Simulink model of the CO2 pack controller, establishing a closed-loop connection between the two systems. This setup facilitated the analysis of the dynamic interaction between the control actions and the system response.

Using this co-simulation framework, the performance of the original cabinets and pack control strategies (baseline) were compared with those of improved strategies aimed at maintaining a higher and more stable evaporation pressure. Performances were assessed in terms of annual power consumption of the compressor pack, coefficient of performance (COP), and number of compressor starts/stops. The investigated control settings were finally tested in the actual supermarket for demonstration.

Field trials were conducted in two different supermarkets to validate the simulation results. The two supermarkets were the Fakta store in Otterup, which was also used for model development, and the SuperBrugsen store in Otterup. The latter has the same characteristics as Fakta, but it is larger in size.

Table 1 gives an overview of the investigated control strategies:

|

Control |

LT group |

MT group |

Cabinets |

|

Ther (Baseline) |

Step control |

Variable + Step control |

ON/OFF |

|

Stp+VarStp+MTR |

Step control |

Variable + Step control |

Modulating |

|

IdVar+Ther |

Variable speed (Ideal) |

Variable speed (Ideal) |

ON/OFF |

|

IdVar+MTR |

Variable speed (Ideal) |

Variable speed (Ideal) |

Modulating |

Table 1: Overview of the investigated control strategies.

“IdVar” and “VarStp” refer to the compressor control mode and stand for “Ideal Variable”, and “Variable + Step control”, respectively. “Stp” stands for step control. "Ther” and “MTR” refer to the control mode of the display cabinets and stand for “Thermostatic” (i.e. ON/OFF) and “Modulating temperature regulation”.

Key findings

Switching from thermostatic to modulating control led to an improvement in the annual performance (COP) of about 2−2.5 % for the LT group, and of about 7 % for the MT group. A significant reduction in the average number of compressor starts/stops was also achieved.

|

Medium-temperature compression group |

Baseline |

Stp+VarStp+MTR |

IdVar+Ther |

IdVar+MTR |

|

COP |

4 |

4.5 |

4.5 |

4.7 |

|

Number of average start/stops |

34 |

8 |

0 |

0 |

|

|

|

|

|

|

|

Low temperature compression group |

Baseline |

Stp+VarStp+MTR |

IdVar+Ther |

IdVar+MTR |

|

COP |

1.74 |

1.78 |

1.92 |

1.96 |

|

Number of average start/stops |

68 |

62 |

4 |

4 |

Table 2: Simulation results.

Field trials confirmed the simulation results and yielded evidence of the efficacy of digital twins in optimizing the performance of the system. Figures 3 and 4 show the distribution of the evaporation pressure of the MT and LT suction group, respectively, before and after changes in the original control settings, which consisted of the switch of the cabinet control mode from thermostatic to modulating temperature regulation. A higher stability in the evaporation pressures can be noted under the modulating temperature control.

Figure 3: Medium temperature (MT) evaporation pressure fluctuation in real system for thermostatic (THER) and modulating (MTR) control mode.

Figure 4: Medium temperature (LT) evaporation pressure fluctuation in real system for thermostatic (THER) and modulating (MTR) control mode.

In addition to stabilising system operation, the switch from thermostatic to modulating temperature control also led to significant reductions in compressor power consumption (figure 5). In MTR mode, the compressor power consumption was reduced by an average of 5-6 % compared to that required by thermostatic control over the entire operating range. This suggests that the annual energy consumption could be reduced by the same percentage.

Figure 5: Variation in the compression power consumption resulting from the field trials.

Concluding remarks

The project successfully developed a digital twin framework for the analysis and optimization of supermarket refrigeration systems and demonstrated that digital twins can improve cost-effectiveness and energy efficiency. In particular, it has been shown that:

- The mutual interaction between the controllers of the display cabinets and the compressor pack strongly influences the stability of the evaporation pressure, hence the system performance. Therefore, to optimize the latter, the control action must minimize fluctuations in the evaporation pressure.

- The most cost and energy-efficient operations of a supermarket refrigeration system can be achieved by equipping the suction group with a variable-speed compressor and adopting a modulating regulation of the temperature of the display cabinets. This would ensure a more stable evaporation pressure and load and, hence, a more stable and efficient operation of the compression group.

- The adoption of digital twins represents a paradigm shift in the management and optimization of supermarket refrigeration systems and together with advanced analytics, machine learning algorithms and IoT sensors pave the way for autonomous, self-regulating refrigeration systems capable of adapting to dynamic boundary conditions and environmental factors, thereby enabling supermarkets to achieve higher efficiency, lower operating costs, and greater sustainability.