Numerical modelling

Numerical models, which represent the physical system. The models may have a different level of detail and will be tailor-made for the respective services.

Numerical models are mathematical models, which are used to describe a certain process. The models may be of different complexity and be based on different approaches. In this project, most of the considered models are dynamic, thermo-hydraulic models, which are based on a set of differential-algebraic equations.

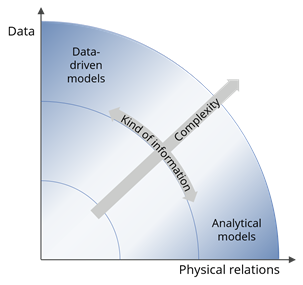

The information content of the numerical models can be based on data and physical relations. Typically, analytical models imply a high degree of physical relations, while data-driven models are mainly based on measurement data. However, there is a certain transition phase between the two approaches and in reality, numerical models are often based on a combination of both physical relations and data.

Figure 1: Visualization of different modelling approaches.

The level of complexity determines the effort for the creation and the numerical resources during calculations as well as the information, which may be provided by the models. The aim is to keep the level of complexity as low as possible while the level of information is kept sufficiently high in order to fulfill the intended services.

The objective is to reduce the effort associated with the modelling activities in order to facilitate the deployment of digital twins in a broad range of applications. This is achieved through a modular and flexibly combinable modelling approach to ensure a good reusability and adaptability of the numerical models.

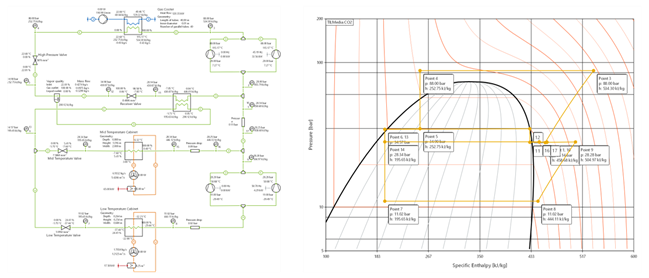

The current project comprises modelling activities for both supermarket refrigeration systems and heat pump systems. Supermarket refrigeration systems are subject to various unknowns regarding the final as-built layout as well as the operating loads. This requires parts of the system to be modeled based on measurement data rather than on an exact physical description of the system. Large-scale heat pump systems are instead well documented and may be modeled with a high degree of physical information. The analytical models will to a large extent be based on the TIL library from TLK-Thermo.

Figure 2: Flow sheet (left) and p-h-diagram of CO2 supermarket refrigeration system (Diagrams from TLK-Thermo).